A client in the pulp and paper industry came to us with a unique challenge: ensuring that only clean wood, free of any bark residue, entered the pulp production process. The presence of residual bark was impacting both the efficiency and quality of the final product and adding extra costs for wood treatment.

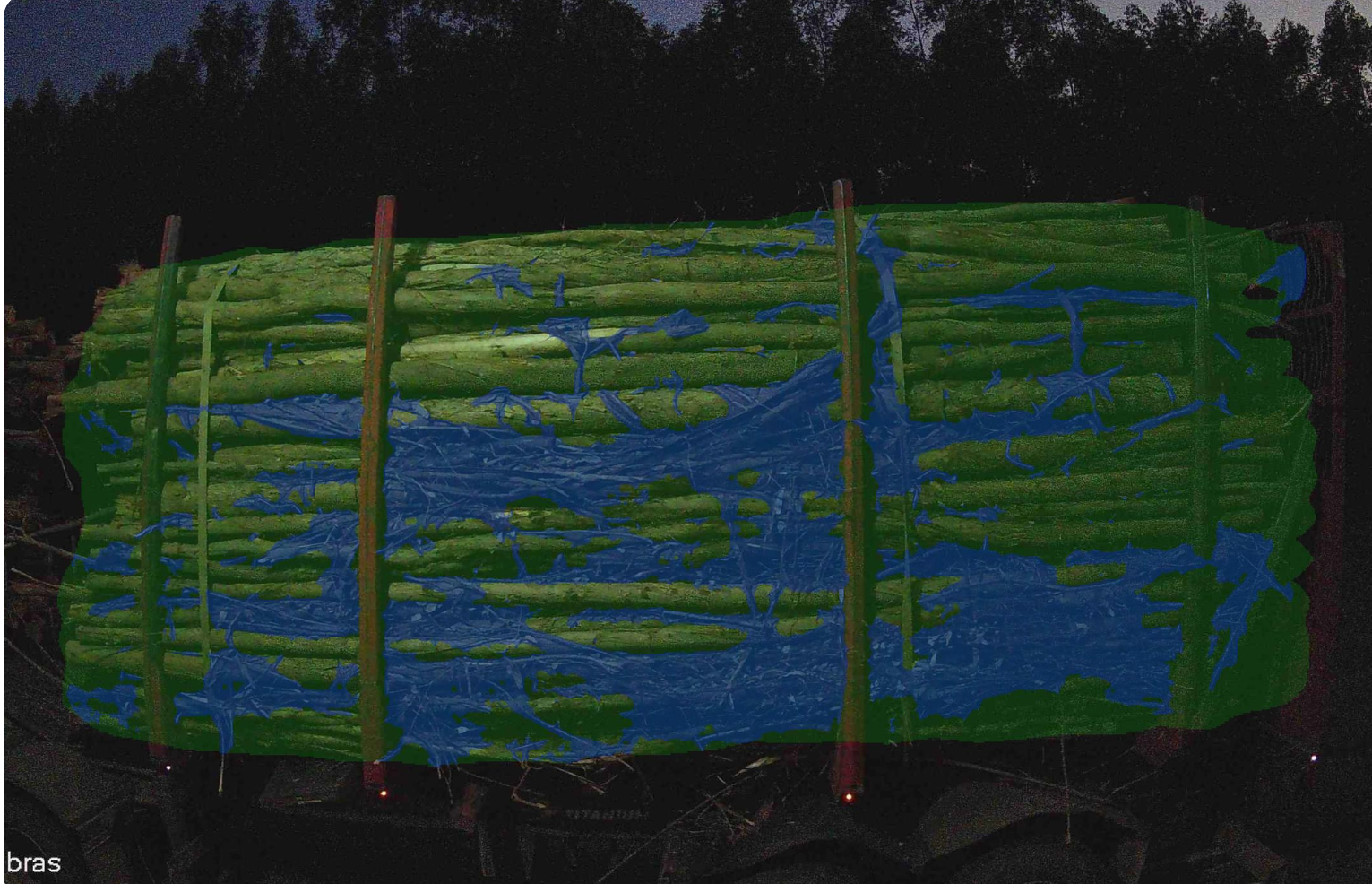

To address this challenge, we implemented the Vision Module from our Vision Control system. Utilizing high-resolution cameras and advanced algorithms, the system was optimized to inspect each log in real time, pinpointing areas with remaining bark and allowing for immediate corrections. Integrated with the factory’s automation systems, Vision Control automatically redirects logs that need an additional debarking cycle, ensuring a cleaner and more efficient production process.

Since the implementation, the client has experienced significant improvements in the quality of processed wood, with reduced waste and consistently high standards of purity in the final product.